100% Soluble Humic Acid Humate Sodium Wood Stain Absorbing Toxins Sodium Humate

Product Description

100% Soluble humic acid Humate Sodium Wood Stain Absorbing Toxins Sodium Humate

Product Description

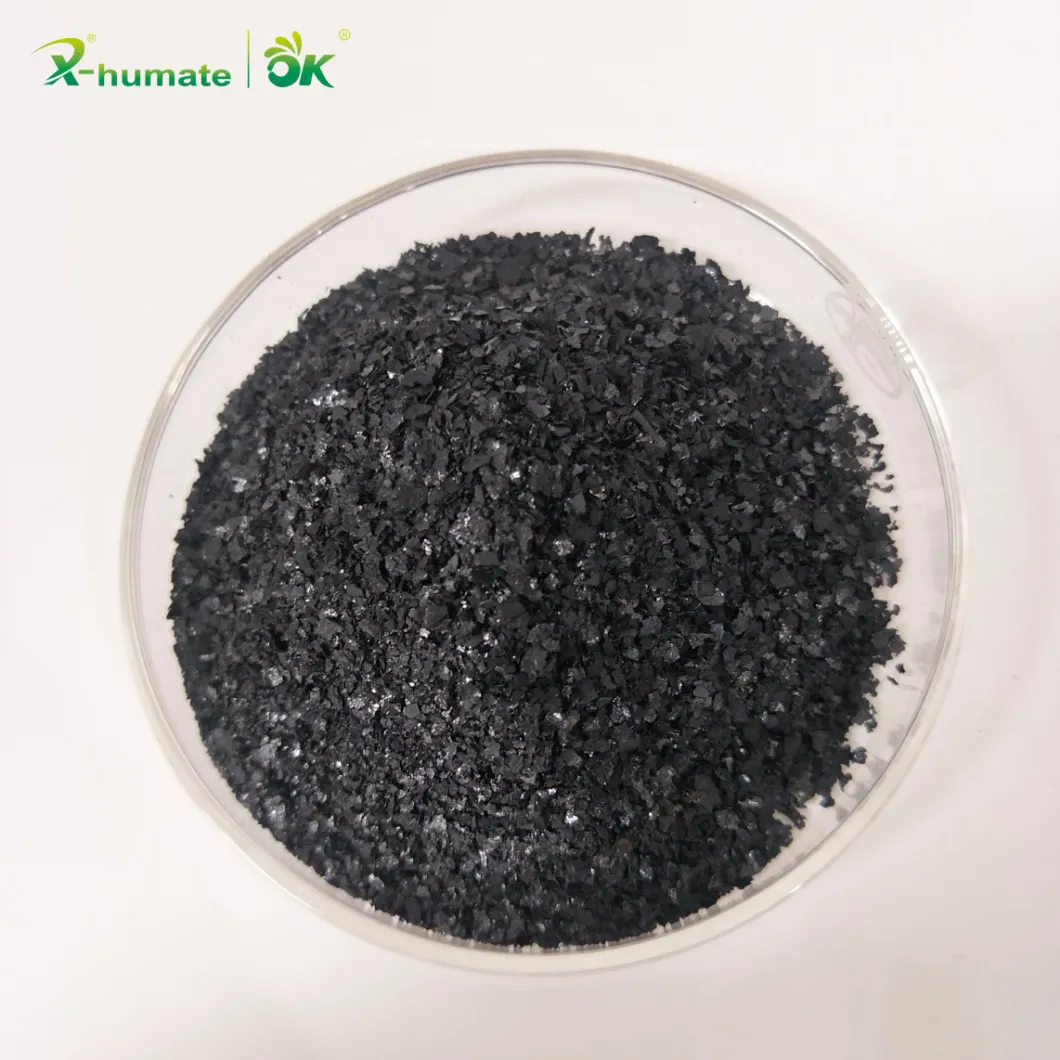

100% Soluble Humic Acid Humate Sodium Wood Stain Absorbing Toxins Sodium Humate Flake/Powder is a sodium salt of humic acids, produced from lignite. It is natural mordant, soluble in alkalis and water. It is shiny flakes. The basic coloring components are humic acids. Nut mordant acts as a complex agent, which apart from its coloring effects, helps to improve physical characteristics of final product. Connection with the favourable price creates good conditions for its application in production.

Specification

Application

100% Soluble Humic Acid Humate Sodium Wood Stain Absorbing Toxins Sodium Humate Flake/Powder is used for coloring of paper, especially cardboard and wrapping.

A) MASS DYING

Mordant is usually added into the broke beater soluted in water in concentration from 1:4 to 1:10 or directly in the form of solid flakes.

The content of nut mordant is, according to desired shade of colour, 2-8% of the dry paper matter (dried in the open air). The matter is mixed properly and then is added solution of aluminium Sulphate Al2(SO4)3. This solution regulates the fine precipitation of dyestuff. should be achieved The acid medium (pH value about 5) is optimal for proper precipitation. Then, after pressing the paper stuff, the outflowing water should be clear.

B) SURFACE DYING

Surface dying is usually done on the size press, where 10% solution of the Nut mordant is distributed on the upper layer and at the same time is on the bottom layer distributed colored or uncolored starch. Into the defibred paper is usually added solution of aluminium sulphate Al2(SO4)3 before spraying on the rolls. Nut mordant consumption is according to the desired shade about 0,25% of mass, related to the weight of the upper layer, dried in the open air.

When necessary to obtain specific shade of color, Nut mordant is very good mixable with other commonly used colors.

Characteristics

Colored paper has very good fastness to light.

Reactivity of humic acids improves density, surface strength, puncture and bending resistance, initial tearing strength and sizing of the final product.

Total yield grows up because the mordant has gone, under optimal conditions, entirely into the paper.

Chemical structure of nut mordant helps to regulate moisture in the final product.

High chemical reactivity helps to form bonds with heavy metals during the production process, which prevents uncontrolled coagulation and improve purity of waste water.

Packing & Delivery

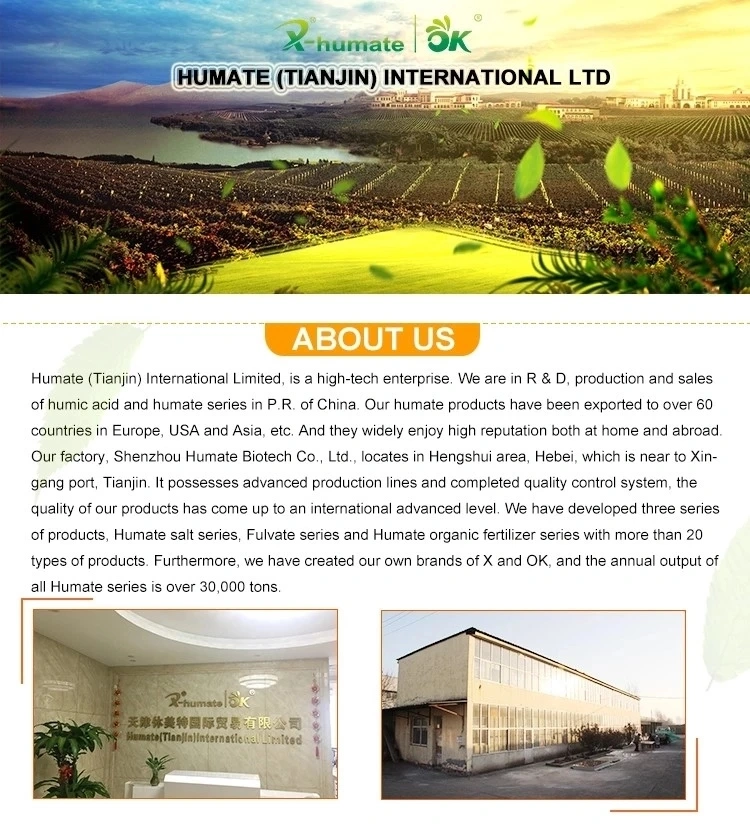

Our Company

Contact us if you need more details on Sodium Humate. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Humic Acid、100% Soluble. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Description

100% Soluble Humic Acid Humate Sodium Wood Stain Absorbing Toxins Sodium Humate Flake/Powder is a sodium salt of humic acids, produced from lignite. It is natural mordant, soluble in alkalis and water. It is shiny flakes. The basic coloring components are humic acids. Nut mordant acts as a complex agent, which apart from its coloring effects, helps to improve physical characteristics of final product. Connection with the favourable price creates good conditions for its application in production.

Specification

Item | Standard | ||

Water Solubility | 100% | ||

Humic Acid (dry basis) | 65%min | ||

Moisture | 15%max | ||

PH Value | 8-11 | ||

Appearance | Powder/Flakes |

Application

100% Soluble Humic Acid Humate Sodium Wood Stain Absorbing Toxins Sodium Humate Flake/Powder is used for coloring of paper, especially cardboard and wrapping.

A) MASS DYING

Mordant is usually added into the broke beater soluted in water in concentration from 1:4 to 1:10 or directly in the form of solid flakes.

The content of nut mordant is, according to desired shade of colour, 2-8% of the dry paper matter (dried in the open air). The matter is mixed properly and then is added solution of aluminium Sulphate Al2(SO4)3. This solution regulates the fine precipitation of dyestuff. should be achieved The acid medium (pH value about 5) is optimal for proper precipitation. Then, after pressing the paper stuff, the outflowing water should be clear.

B) SURFACE DYING

Surface dying is usually done on the size press, where 10% solution of the Nut mordant is distributed on the upper layer and at the same time is on the bottom layer distributed colored or uncolored starch. Into the defibred paper is usually added solution of aluminium sulphate Al2(SO4)3 before spraying on the rolls. Nut mordant consumption is according to the desired shade about 0,25% of mass, related to the weight of the upper layer, dried in the open air.

When necessary to obtain specific shade of color, Nut mordant is very good mixable with other commonly used colors.

Characteristics

Colored paper has very good fastness to light.

Reactivity of humic acids improves density, surface strength, puncture and bending resistance, initial tearing strength and sizing of the final product.

Total yield grows up because the mordant has gone, under optimal conditions, entirely into the paper.

Chemical structure of nut mordant helps to regulate moisture in the final product.

High chemical reactivity helps to form bonds with heavy metals during the production process, which prevents uncontrolled coagulation and improve purity of waste water.

Packing & Delivery

Our Company

Contact us if you need more details on Sodium Humate. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Humic Acid、100% Soluble. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : humate series > Sodium Humate

Premium Related Products

Other Products

Hot Products

99% min food grade CAS 144-55-8 NaHCO3 Sodium Bicarbonate baking sodaNew refrigerant gas pentafluoropropane R245fa99.6 Oxalic Acid As Chemical Raw Material99.5% Maleic Anhydride As Plasticizer In Plastic IndustryCAS 420-04-2 CyanamideN-ButanolIndustrial Grade Solvents And Chemical 99% DIPE Diisopropyl Etherfactory price high quality Feed Grade Raw Material Animals Additives 98% 99% Calcium Formatein china manufacturer market price suspension grade for pipe 100% virgin pvc resin sg5 pvc resin k65 k66 k67High Quality 99% Min Naoh Market Price Of Caustic Soda Flakes ManufacturerCas No115-77-5 Industrial Grade 95% 98% PentaerythritolNano water stickwater filter cartridgeleather rubber industry 25 kgs drum IBC drum producer formic acid 85%,94%,99%Powder Aluminium SulphateFar Infrared Ceramic Ball